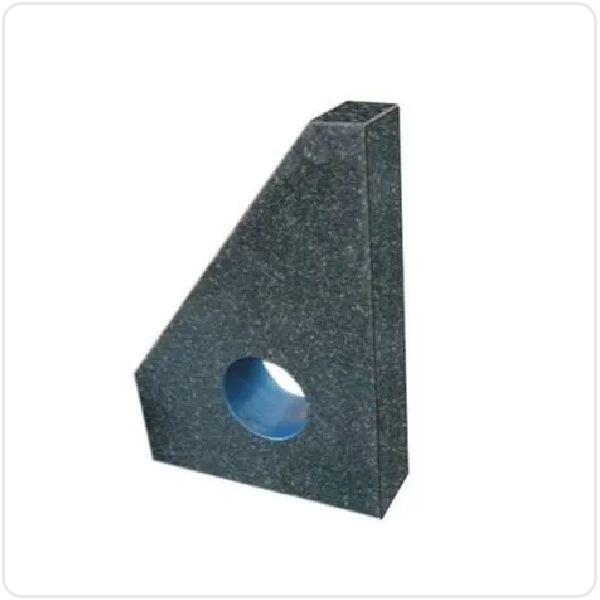

Product Description

Granite square are made of selected black granite. These triangular shaped granite squares are ideal for checking X, Y and Z axes of machine bases or parts. They are very rigid and stable. The two face master angle has two narrow perpendicular edges finished flat and square.

Product Specification

| Size (mm) | Accuracy (um) |

| 300 x 200 x 63 | 5 |

| 400 x 250 x 63 | 6 |

| 500 x 300 x 80 | 6 |

| 600 x 400 x 100 | 8 |

| 1000 x 600 x 100 | 10 |